Case Studies

-

![]()

Complexity study to help Concept Selection process

A study was conducted to compare different concepts for using gas turbines, gas engines, and electric motors in an Unmanned LNG design for a major IOC. While engineers could assess each type of equipment separately, a broader approach was needed to measure complexity across all types. The review found that LNG trains powered by electric drives with a specific compressor setup were the least complex. Additionally, gas turbines used for power generation required the fewest personnel on site and also offered the lowest capital expenditure for the design.

-

![]()

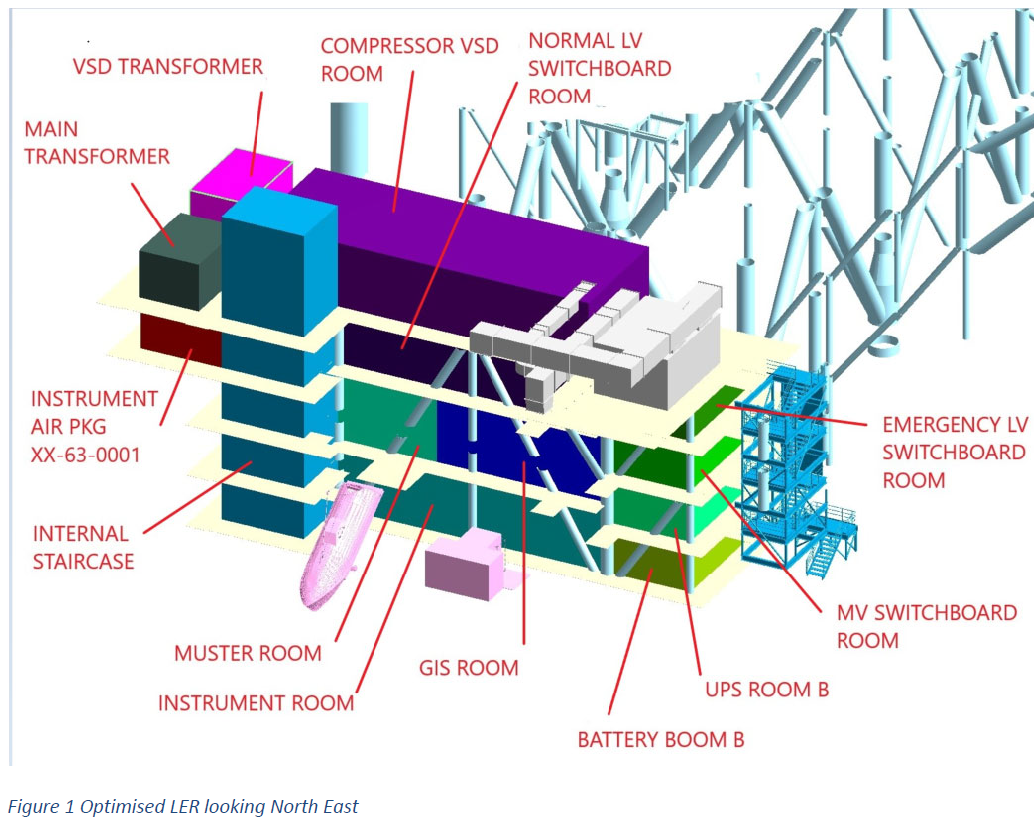

FPSO NUI Design

For a Norwegian deepwater gas project, we managed the early Operations Readiness stages of development and prepared for operations to shift from a manned to an unmanned FPSO. This change lowered both capital and operating costs while keeping high availability. It needed a solid grasp of Norwegian regulations and NORSOK standards. The new operating model also required fresh approaches to logistics, onshore support, and risk management for critical events.

-

![]()

Divestment Support

A major IOC wanted divest all assets and exit a country, requiring confidential operational support due to local government and personnel sensitivities. This limited available assistance from the existing operations team to assist the commercial process. During internal reviews, several key documents were identified that could have allowed potential buyers to negotiate a lower price if not updated properly. The commercial team were provided with guidance on future facility uptime and expected operating costs, helping them set a Minimum Agreed Sale Price that was about 30% higher than the original price based only on business plans. There was continued assistance with the divestment process until it was publicly announced, at which point the Asset team took over.

-

![]()

Post FEED Optimisation Management

An offshore gas project finished its FEED stage but could still improve the design. We conducted a study for the Operator and collaborated with the main FEED Contractor to find several improvements, including:

- Simplifying the condensate offloading system

- Reducing structural requirements

- Eliminating telecom and radar systems

- Improving seawater system materials

- Lowering facility inlet pressure piping

- Shortening the offshore commissioning phase

These changes resulted in a CAPEX reduction of about USD 100 million and a weight decrease of 1,010 tons from an initial topside weight of around 11,000 tons.

-

![]()

W2W / CSOV Logistics

Developing a W2W/CSOV strategy for a project in tough weather conditions involved defining the vessel's expected functions, exploring the market, and presenting options to the Project Team. This was done early (before FEED) since available options could influence design choices for the topside facility. Choosing an effective W2W strategy led to eliminating the helideck, reducing weight, and simplifying utilities. It also led to a greater than USD100m saving during offshore commissioning phase.

-

![]()

OPEX Development

Early phase projects often use a portion of CAPEX as OPEX, which is a proven, robust method. However, some situations need more detailed OPEX information sooner than usual. In a pre-FEED project developing a new unmanned Operating model, the team needed to understand the key OPEX factors for economic evaluation. The standard percentage of CAPEX did not adequately reflect the benefits of being unmanned, so they created a detailed Activity Based Cost Model using the client’s maintenance data and equipment, adjusted for the new model. This OPEX model clearly identified major OPEX factors and facilitated risk analysis of these components, aiding in the Concept Screening of various options.

Understand our Services

Find out what we can do to help your Project and Assets be Safer, Faster, Better.